Do you know how to keep your draft system healthy?

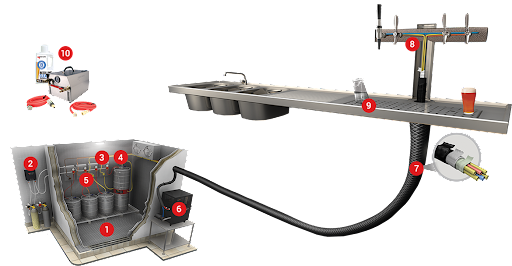

10 Key Elements of A Draft System

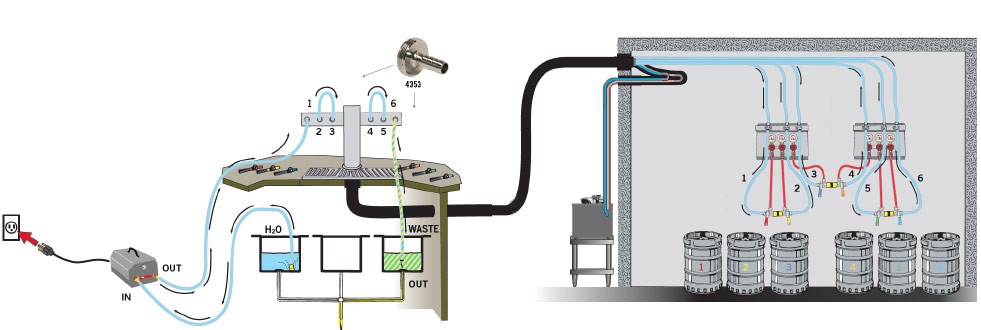

Many components go into a draft system, so let’s look at a brief overview to get us started.

Follow this diagram by matching the number to the description below!

- Keg Storage: Dedicate a walk-in cooler for kegs and maintain a temperature of 38°F. We will dive into why this temperature is so important later.

- Gas Blenders: These maintain the proper amount of carbonation.

- The Secondary Regulator Panel: Ensures each keg receives the optimum pressure.

- Stainless Steel: Improves system cleanliness and hygiene.

- PRO-MAX: Also known as the profit maximizer or FOB, it maximizes the ROI of a keg.

- Power Pack: Maintains the proper temperature.

- Trunkline: Maintains beer integrity while preventing cross-line flavor contamination.

- Draft Towers: Last step in maintaining a proper temperature.

- Glass Cleaning: Clean glasses improve the taste, quality, and aroma of the tapped beverage.

- Cleaning and Maintenance: An unclean system affects the taste and quality of the drink.

If you are a visual learner, Micro Matic created this video highlighting these 10 elements.

Now you have a brief overview of the main draft system components, so let’s get right into the details.

Walk-In Cooler

No matter what, the most important thing to keep in mind is the cooler because it stores all your tapped products. Since it is such a crucial part of operations, you need to build it properly.

Make sure your cooler is big enough to hold backup kegs. If you replace an empty keg with one stored in your basement, the beer will be warm. Yuck! If you are moving a warm keg of beer to the walk-in cooler, the general recommendation is to leave the beer in the cooler for at least 24 hours before tapping it.

There must be enough space for your staff to move around in your cooler. The more cluttered and congested the cooler is, the less likely your workers are to go in and check on the kegs, temperature, and gas pressure. The general rule of thumb is to stick with 2 ½ square feet per faucet.

The magic temperature for a walk-in cooler is 38 degrees Fahrenheit for most carbonated products. 36 to 40 degrees is a good working temperature. If the walk-in temperature is more than 40°F, the beer will appear warm. If it is colder than 36°F, the beer will be too cold.

Despite all the hype around an ice-cold beer on a hot summer day, there are negative repercussions if it is too cold. While it may be refreshing, the beer will have little taste. If the temperature is too low, the beer will have almost no aroma and a dampened flavor. Have a server in charge of checking the cooler temperature daily to ensure it is at the desired temperature.

But sticking to this sweet spot may not work for all your beverage offerings. Say you are looking to sell a stout that is best kept around 45°F. What do you do? Do you compromise your 30 other kegs to have that one stout turn out right? No, and unfortunately, offering different beer styles on tap can be difficult. Some bars and restaurants do choose to serve different beer styles warmer to enhance the aroma and flavor. To offer this, you must have different coolers to house the different styles. This method ensures each beer keg is at its ideal temperature.

Now, let’s move inside the cooler and talk about how the beverage gets from keg to glass.

Two Types of Draft Systems

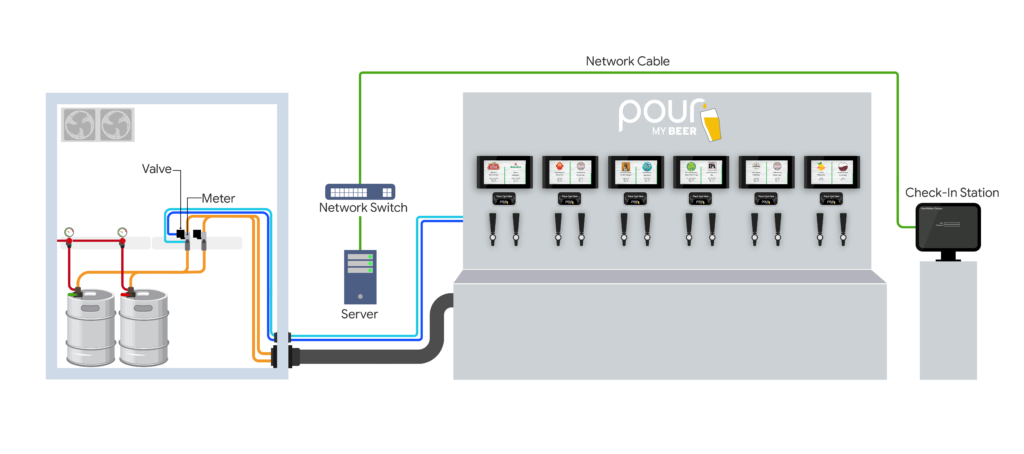

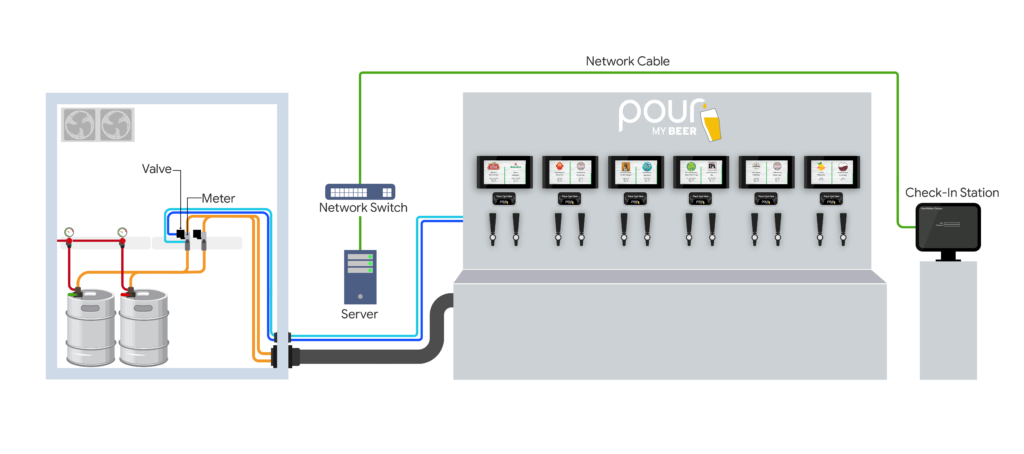

There are two types of draw systems for dispensing, the long-draw system and the direct draw system.

Long-Draw

With a long-draw system, coolers can be 150+ feet away from the taps. In most cases, the cooler is not near the dispensing taps. For example, the cooler is in the basement and the self-pour wall is on the main dining floor.

A long-draw system is more expensive because there is more equipment needed. When a keg empties, beer remains in the line. Since the distance from the keg to the faucet is much longer in a long-draw system, there is more beer waste. Be aware of this and find good use of the beer that is in the line. Some restaurants use it to cook or for their own consumption or even put it back in the keg, but in the United States, this is illegal.

The advantage to this system is that the cooler is not taking up too much of your floor plan. The cooler can be in the basement or an area not used for seating.

Direct-Draw

In a direct-draw system, the dispense faucets connect to the cooler. This system makes it easy to find the route of issues if something goes wrong because it is all right in front of you. It is not separated by a floor or in a different room in your establishment. If you have a self-pour venue, then your beer shank, tap, and screen mount onto the other side of the cooler wall.

Deciding on which system is right for you can take time. Think of your floor plan and how to best use your space. Some establishments are built around the beer taps, and for others, it is the last thought.

Gas Blender

Thanks to the perfect blend of CO2 and Nitrogen, the last pour tastes as good as the first. A gas blender takes the perfect ratio of the two inputs and mixes them while protecting the integrity from keg to glass. Too high or too low input pressures will cause the blender to malfunction and not allow the customer to pour.

Carbon dioxide is naturally in beer. Without getting too technical, carbon dioxide is produced mainly during the preliminary fermentation process. It creates the “fizz” in beer. Excess CO2 collects throughout the fermentation phases and gets added back into the final product. Nitrogen has no taste or scent, so it does not affect the integrity of the beer. Its purpose is to push the drink through the tubes and into the glass.

This combination helps with temperature fluctuations and keeps the beer tasting as it should. It is important to monitor the gas because you never want your customers to pour an over/under-carbonated beverage. Choose a staff member to be in charge of gas because it often gets forgotten. It is important to remember that if there is no gas, there is no beer!

FOBS and Flowmeters, Your Profit Maximizers

Foam buster, keg savers, foam on beer (FOB), we’ve heard it all. A FOB’s job is to shut off beer lines when the keg empties. FOBs are 100% mandatory with the PourMyBeer self-pour beverage system to prevent customers from paying when no more beer is in the keg. When a keg empties, the flowmeter measuring the amount of liquid traveling through the line closes. Also, a flowmeter valve opens and closes depending on if a customer has a valid RFID card. These two parts go hand in hand to ensure the customer is not charged when the beer stops flowing.

Fob

Flowmeter

The Lines

Although it is pretty self-explanatory, lines carry beer, wine, cocktails, kombucha, cold-brew, or soda from the keg to the faucet. They are a vital part of the draft system and experience wear and tear during the pouring process.

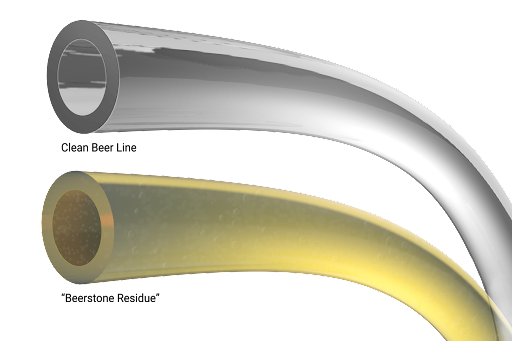

Biweekly Line Cleaning

Almost all domestic draft beer in the U.S. is not pasteurized. This means that it is alive and full of yeast and bacteria that grow and multiply quickly. Yeast and bacteria affect the clarity, taste, smell, and aroma of the drink. Because beer is living, everything that it touches gets dirty within 3 to 10 days. The rule of thumb is every two weeks you must clean your beer lines.

Line cleaning involves working with dangerous chemicals, so train your staff how to use them. Flush all chemicals out of the lines so your guests do not end up consuming them. Make sure you are not using products with Chlorine in them. Chlorine eats stainless steel, burns the inside of the tumbling, and can even burn pinholes in the lines.

Line Cleaning Methods

Static soak

For a static soak, you need a canister or keg to hold the chemicals. You will remove the beer keg and reattach the canister. Water will push the excess beer out of the lines, and then you can hit the lines with the chemicals.

Think about letting your clothes soak in the sink when you wash them.

Recirculation

The recirculation method uses a machine to force the liquid through the lines. This method is more of a scrub as opposed to a soak. Like our past comparison, picture this method like throwing your clothes in the washing machine where they can agitate. This method is 80 times more effective than the static method.

Quarterly Line Cleaning

Once a quarter, clean your lines with an acid cleaner. This acid cleaner helps remove beer stone, which is a calcium deposit that forms inside the brewing equipment. Make sure chemicals are not mixed during the cleaning process.

The Exterior

The wall itself

Of course, we cannot forget about the beautiful self-pour wall our customers see and love! Since the self-pour beverage wall will likely be a highly visited spot in your establishment, you must keep it clean!

Wipe down taps, drip trays, screens, and RFID holders on a nightly basis. They are heavily touched areas and need to be ready for the next day. There are special brushes that you can stick inside the taps each night to clean them out, or you can use soda water to soak/flush out the taps.

Come work with us!

Tim Enarson, from Navigator Taproom, explains how Micro Matic’s draft system equipment and PourMyBeer’s tech work together to give customers a truly unique experience

Check out what it is like to work with PourMyBeer and Micro Matic, below.

Glass cleaning

Clean glasses are a must. Refresh the soap and sanitizer several times a shift. Busy shifts are great, but you must remember that more people are drinking. More glasses are getting washed in soap and sanitizer, which leads to soil buildup. Since it is a wash, rinse, and sanitize cycle, more water gets into the sanitizer, diluting the solution. To avoid all scenarios mentioned above, change the cleaning products regularly. Check the pH levels in the sanitizer to test the strength because you do not want it too strong or too weak.

The pH must be right on track to be effective, but you must let the glass air dry to get the best results. Sanitizer works through contact time. It is crucial to give the glass time before putting it back on the shelf.

Another thing to keep an eye on are the glass cleaning brushes. Because of how often they are used, they tend to matt down somewhat quickly. Make sure they are fresh and that you clean them and let them dry out. Ensure the brush is long enough and wide enough to clean the whole glass.

Why is keeping your draft system healthy so important?

The answer is simple. The healthier your draft system is, the happier your customers will be, and the more profits your establishment will make.

All in all, a lack of maintenance will hurt your return on investment. If the draft drinks do not taste the way they should, or the glasses aren’t squeaky clean, customers will go to another restaurant, bar, brewery, or taproom. Bad quality beer affects the bottom line. Draft system equipment is not cheap, but if maintained, the profits far outweigh the costs.

Don’t forget to share your draft system knowledge with your friends!

want to learn more?

We hosted a webinar with Micro Matic and spoke with David Green, a Dispense Trainer. In this webinar, he covers draft system essentials, maintenance and cleaning, and troubleshooting common issues. He provides tips and tricks and answers questions about keeping your draft system running smoothly.

Watch the webinar to become an draft system expert, now!